In today’s ever-changing economy, the supply chain industry is going through a transformation. We are witnessing a shift, from supply chain operations thanks to the emergence of disruptive technologies such as Artificial Intelligence (AI) and Machine Learning (ML). These advanced capabilities of AI and ML are playing a role in transforming the supply chain industry.

In this article, we will explore the direct impact of both artificial intelligence and machine learning on supply chain analytics and their overall contribution to the sector.

- The Challenges in Traditional Supply Chain Processing

- Artificial Intelligence and Machine Learning in today’s world

- Key Technologies Powering Analytics in AI/ML

- Benefits of Artificial Intelligence and Machine Learning in the Supply Chain Industry

- 1. Providing Decision Makers with Data-Driven Insights

- 2. Processing, Analyzing, and Visualizing Vast Amounts of Data

- 3. Detecting Patterns in the Supply Chain

- 4. Automation and Optimization in Warehouse Management

- 5. Perform Complex Calculation and Simulations

- 6. Dynamic Pricing Strategies

- 7. Risk Management and Supply Chain Resilience

- Challenges and Ethical Considerations

- Conclusion

Key Facts

- The global AI in the supply chain industry is projected to reach a whooping sum of 41.23 billion by 2030.

- AI growth in the supply chain industry in the forecast period from 2023 to 2030 is at a CAGR of 38.8%

The Challenges in Traditional Supply Chain Processing

Before AI and ML came into play, the supply chain industry faced challenges. These challenges included difficulties in accurately predicting demand, inefficient inventory management systems, manual processes that were time consuming, and suboptimal networks. Over time these issues resulted in inefficiencies, increased costs, and struggles to meet customer demands.

The transformation we are currently witnessing in the supply chain, and the manufacturing sector as a whole, is a response to these challenges faced by logistics operations. For instance, large companies often encounter difficulties in managing and tracking the movement of goods from their source to their destination.

Due to the lack of visibility, there is often a delay in shipments reaching their destination resulting in lead times and increased costs.

Making demand forecasts without thorough analysis often leads to errors or excess inventory. A prime example of this is the effect of 2019 COVID on the supply chain. According to a survey carried out by Genpact, it was found that 70% of businesses have not fully recovered from the effects of the pandemic. The logistics industry suffered greatly due to its disruptions. However, advancements in technologies like machine learning and artificial intelligence have helped address these challenges. Brought opportunities for growth in the supply chain sector.

Artificial Intelligence and Machine Learning in today’s world

With the rise in global transportation and distribution networks, AI and machine learning fit perfectly to the dire needs of real-time data processing in the supply chain and logistics core areas which are product development, procurement, and manufacturing. Research conducted by Statista, indicates that businesses operating in the supply chain industry are expected to witness increased adoption rates of intelligence, between 2022 and 2025.

Key Technologies Powering Analytics in AI/ML

Within the supply chain industry, there are technologies driving analytics within AI/ML frameworks.

These technologies play a role in the operation of modern supply chain industries. Some of these technologies are;

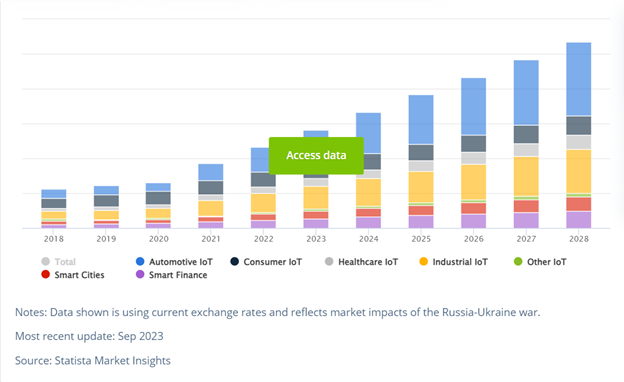

IoT (Internet of Things):

IoT has taken a central stage in the supply chain industry thanks to IoT. The Internet of Things is a crucial element that is massively driving the adoption of artificial intelligence and machine learning in the supply chain industry. The global IoT market is projected to witness a significant upsurge in revenue to a staggering US$1,387.00 billion by the third quarter of 2024. According to research by marketsandmarkets, the global supply chain IoT market size is to grow from USD 18.95 billion in 2022 to USD 34.81 billion by 2027, at a Compound Annual Rate (CAGR) of 12.7%.

The growing need for efficiency in the supply chain industry with a special focus on industry 4.0 smart cities and smart manufacturing offers immense opportunity to the supply chain industry IoT market.

Big Data Analytics:

The supply chain is a crucial part of the manufacturing sector, and a huge volume of data is generated. AI/ML helps in making sense of the vast amount of information by analyzing and extracting useful insights. The integration of AI/ML into supply chain analytics marks a significant shift from reactive to proactive management.

Benefits of Artificial Intelligence and Machine Learning in the Supply Chain Industry

1. Providing Decision Makers with Data-Driven Insights

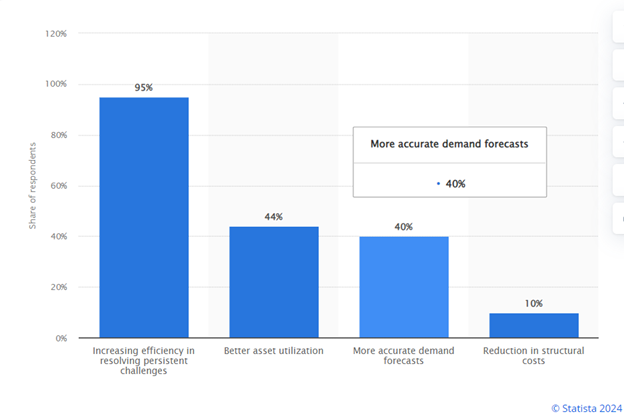

The impact of AI and machine learning cannot be overemphasized in today’s evolving ease of doing business. AI and machine learning have become an integral part of the supply chain industry. From optimizing inventory management to enhancing demand forecasting, AI/ML is here to stay. It has helped in great measure to provide decision-makers with more insights in making data-driven decisions in faster response times and ultimately drive business operational efficiency.

2. Processing, Analyzing, and Visualizing Vast Amounts of Data

The ability of AI and ML to process, analyze, and visualize volumes of data in real-time is invaluable for businesses of all sizes. By utilizing algorithms and machine learning techniques these technologies effectively handle amounts of data from various sources and formats. For example, Blockchain technology which is a distributed ledger helps in the supply chain to track assets and transactions in real-time, which can improve supply chain visibility and reduce the risk of fraud.

3. Detecting Patterns in the Supply Chain

AI and ML techniques excel at detecting patterns, trends, and anomalies within data streams. This enables professionals to gain insights, for tracking supply chain disruptions effectively as well as predicting them ahead of time.

With the implementation of these insights, into day-to-day supply chain operations, we can now pass real-time information. In addition, recommendations and decisions can be made to ensure uninterrupted transportation and logistics services.

4. Automation and Optimization in Warehouse Management

Automation and optimization are now prevalent in warehouse management within the supply chain. The operational technology portfolio has embraced automation to streamline data cleansing and integration processes. This has effectively eliminated data redundancy ensuring consistent data across the value chain. Thanks to the integration of intelligence and machine learning these technologies have greatly improved efficiency in supply chain operations. The deployment of AI-powered robots and automated guided vehicles (AGVs) along with ML algorithms has optimized storage locations and picking routes.

5. Perform Complex Calculation and Simulations

AI and Machine learning are very useful, especially in the simulation processes in the supply chain industry. The ability of these technologies to perform complex calculations and simulations helps in generating reliable and predictive analysis. It also helps in scenario planning that ultimately helps businesses harness the full potential of their supply chain data for improved efficiency and competitiveness.

6. Dynamic Pricing Strategies

AI and ML algorithms can also aid in implementing dynamic pricing strategies by analyzing a plethora of factors such as demand trends, competitor pricing, and supply chain constraints. This enables companies to adjust their pricing in real-time to maximize profitability, improve sales, and respond to market changes more effectively.

7. Risk Management and Supply Chain Resilience

In terms of risk management and supply chain resilience businesses can leverage these technologies to better identify and mitigate risks. By analyzing data from sources like supplier performance, market conditions, geopolitical factors and, even natural disasters these algorithms provide warning signals and recommendations for mitigating disruptions in the value chain. This proactive approach using machine learning helps build resilience within businesses by enabling them to respond to unforeseen events while minimizing the impact on logistics operations and overall customer satisfaction.

Challenges and Ethical Considerations

It’s important to acknowledge that there are challenges and ethical considerations associated with the use of AI and ML in supply chain analytics. Issues such as data privacy, security concerns, and the possibility of bias, in AI algorithms need attention.

In order for big businesses and companies to maintain standards and comply with regulations it is crucial for them to use AI and ML in a way that safeguards data ensuring transparency and fairness, in algorithms.

The immense potential, for AI and ML in the analytics of supply chain processes is promising. As technology continues to advance and provide innovative solutions. With the combination of AI and ML with other emerging technologies such, as the Internet of Things (IoT) blockchain, and augmented reality (AR), supply chain operations will continue to experience increased efficiency, transparency, and resilience.

Conclusion

AI and ML are reshaping analytics in the supply chain industry by providing unprecedented levels of insight, efficiency, and flexibility. As these technologies continue to evolve, they will unlock new possibilities for innovation and improvement in supply chain management.